E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

Mechanical equipment

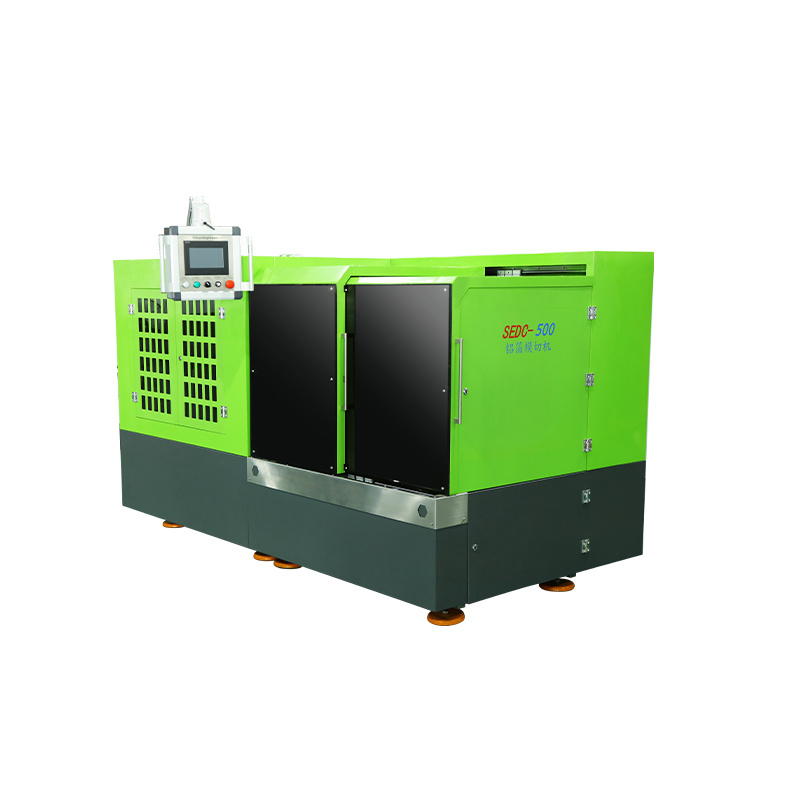

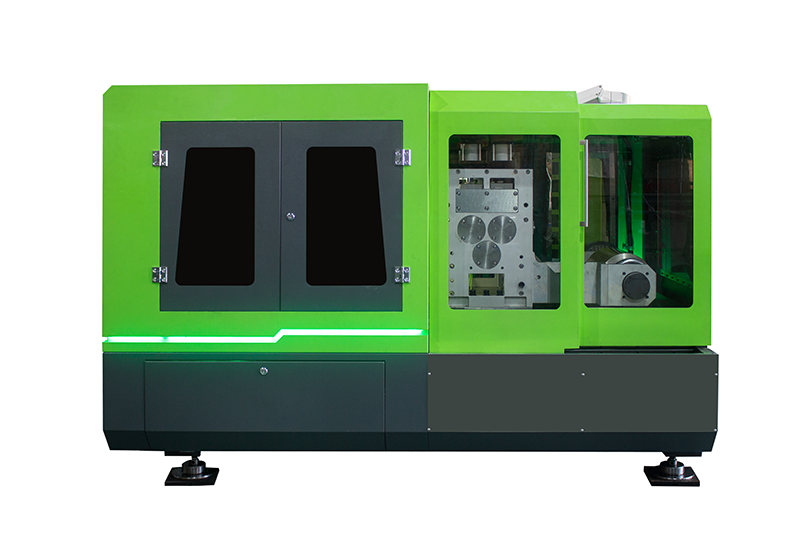

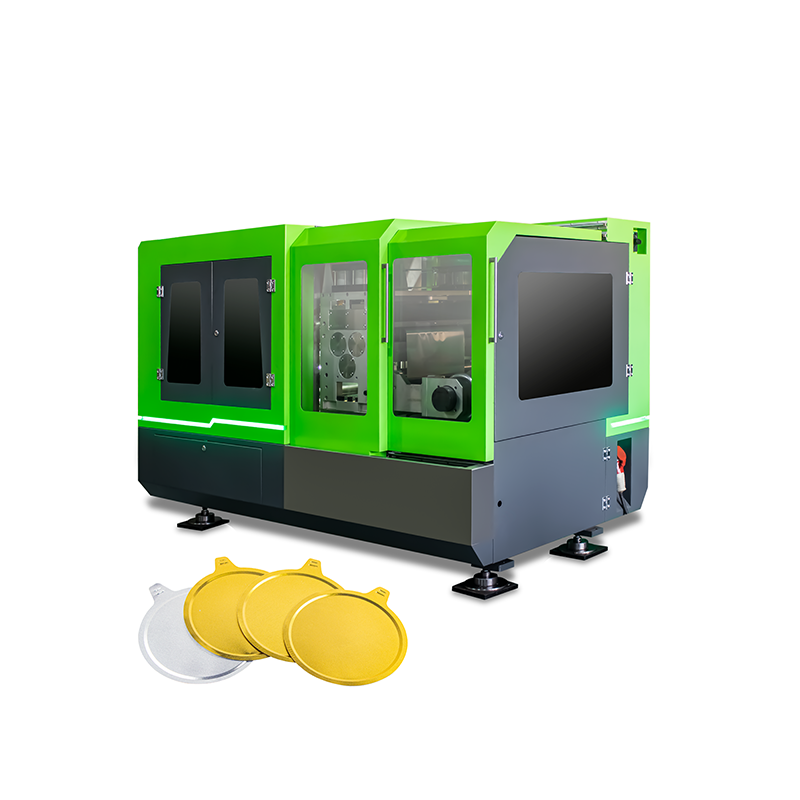

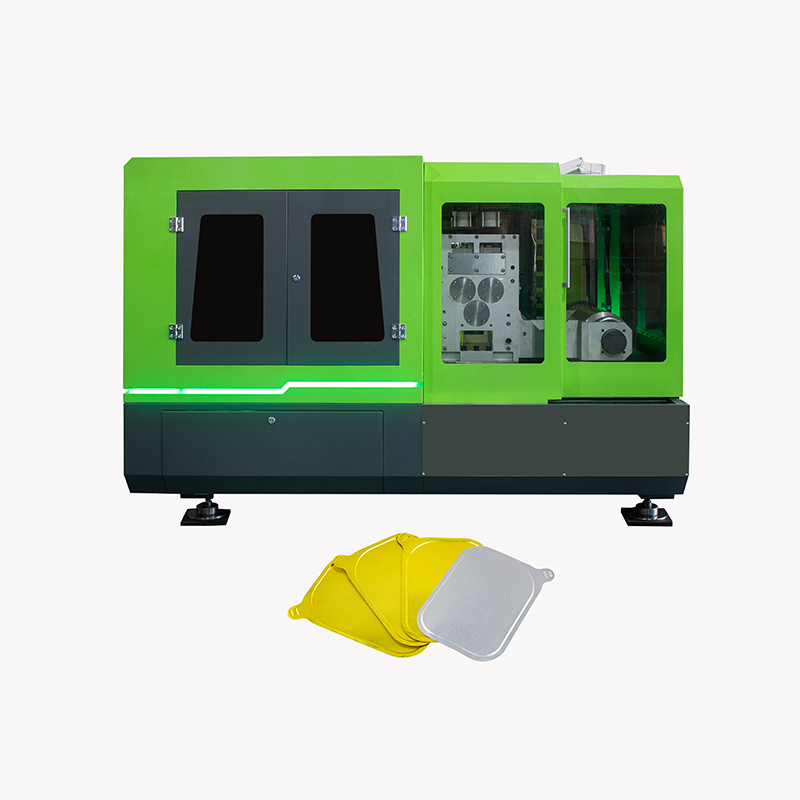

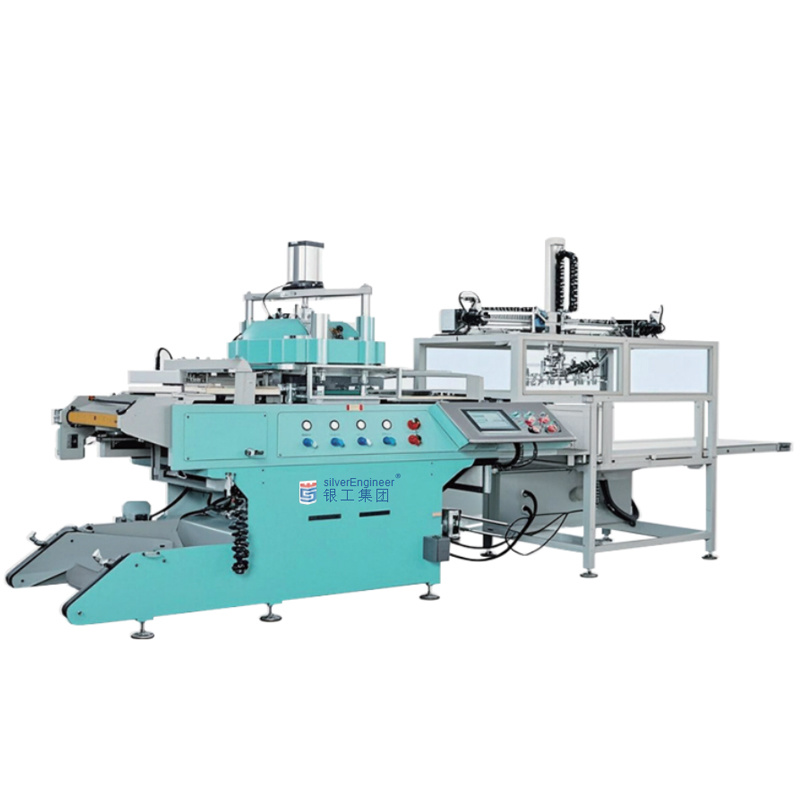

Lid Die Cutting Machine

Key words:

Category:

Details

Drawing of structure

Technical Data

| Model | DC-620 |

| Max. Width of Foil Roll | 480mm |

| Max.Diameter of Roll | Φ600mm |

| Foil Inner Diameter | Φ76mm |

| Die Cutting Speed | 150-200times/min. |

| Max.Mould Dimension | 650x600x180mm |

| Embossing Roll Dimension | Diameter Φ120mm,Length 600mm |

| Main Motor | 5.5KW |

| Servo Motor | 2.2KW |

| Semi Tension Controller | 5KG, Magnetic |

| Auto Deviation Correction | 110 Step Motor Control |

| PLC Brand | Mitsubishi |

| Machine Size | 3000x1500x1800mm |

| Machine Weight | 3500KG |

Description

The Aluminum Lid Die-Cutting Machine can be used to produce and process the heat sealing lid cover of aluminum foil composite coil. After uncoiling the printed composite aluminum foil coil, the embossing effect is processed by the embossing unit. The continuous material detection optical eye controls the tension of the master coil, servo feeding to the die cutting, and the waste edge is pulled and discharged.

Performance

1.The die cutter accessories are made of imported DC53 steel, which is durable and stable after heat treatment and slow wire processing.

2.The embossing unit adopts laser engraving surface treatment, with clear and uniform embossing effect and durability.

3.The design of the tool changing die is excellent. It can be unloaded and pulled directly from the front, which is safe and convenient.

Message

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message