E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

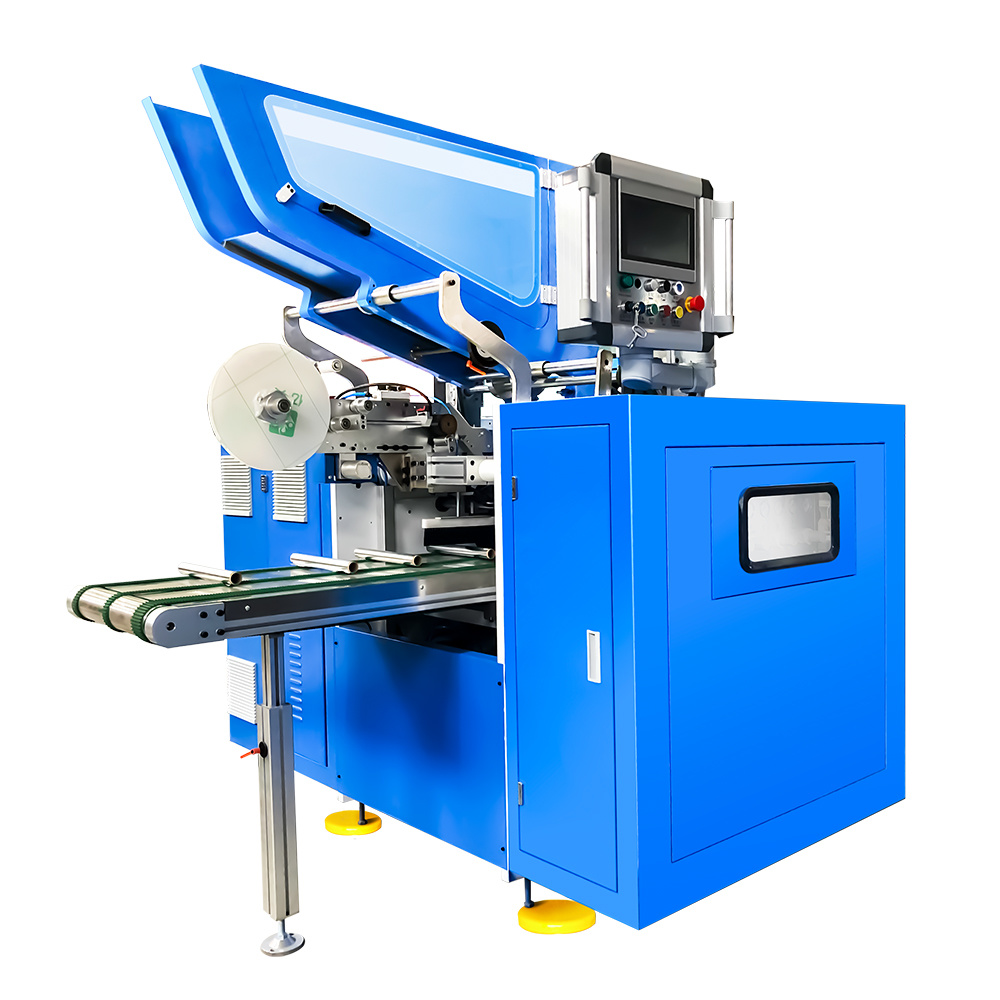

Mechanical equipment

Rewinding Machine

Key words:

Category:

Details

Technical Data

| Model | SEFJ-450-6 |

| Rewinding Material | The Aluminum Foil |

| Rewinding Length | 3-300 m (Maximum Outside Diameter 70mm) |

| Rewinding Speed | 0 ~ 450 m/min |

| Rewinding Thickness Of Aluminum Foil | 0.009~0.25mm |

| Immediate Number | 6 Driven Plus 6 Driven |

| Outer Diameter Of Finished Reel | Maximum 70 mm |

| Inside Diameter Of Paper Core | 30 Standard Size Set |

| The Paper Core Length | 255-470mm |

| The Thickness Of Paper Core | Customer Provides Sample Thickness Not Less Than 1.5mm High Strength Pipe |

| Air Supply | 0.5-0.8Mpa |

| The Power Supply | 380V 50Hz 3PH+N+E |

| Diameter Of Standard Gas Expansion Shaft | 75 mm One |

| The Engine Power | 15KW |

| The Weight Of The | 3200Kg |

| The Machine Size | 3 Meters Long, 2 Meters Wide And 2 Meters High |

Description

The Automatic Rewinder model SEFJ-450-6 which has been specifically studied for producing Household or Catering Rolls of Aluminum Foil, Cling Film and Bakery Paper. Thanks for it's compact design and the programmable working cycle, it can rewinding non-stop with six shafts units and always offers great production performances by the simple operation.It also can connect to Automatic Box Packing Machine for full automatic production line

Advantages

1.This machine is equipped with six shafts group for automatic core loading and keep continuing for working. On this machine the rewinding of material on the Paper Core is automatically by Electronic plus Mechanical, Transmission Mechanism, so as the following operations are carried out automatically:

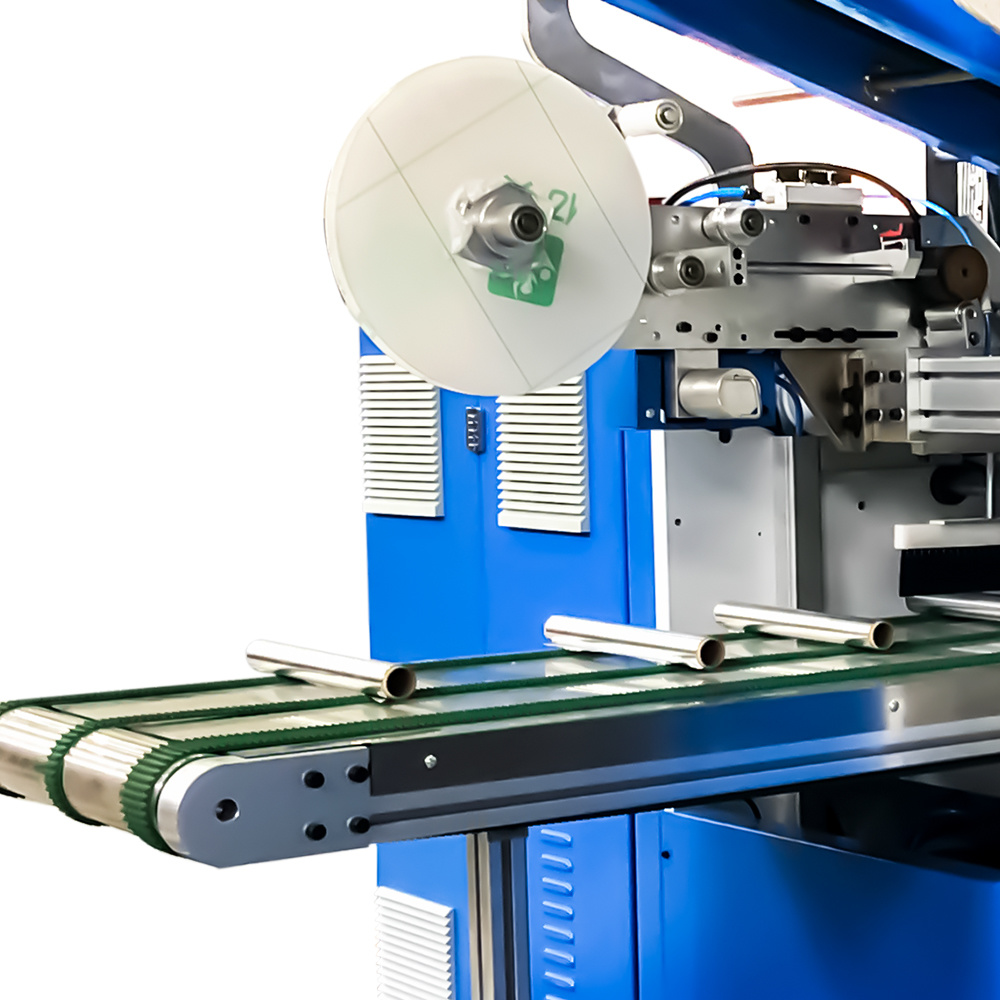

•Automatic inserting of Paper Cores into the rewindingstation

•Automatic material threading onto rewinding core

•Automatic cutting operations

•Automatic movement of the rewinding unit

•Automatic unloading the finished roll

•Automatic rewinding

•Automatic feeding finished rolls out of machine

2.When the machine rewinding the raw material, the paper core does not need to be sprayed with glue, and the raw materials can be rolled perfectly.

Pre: None

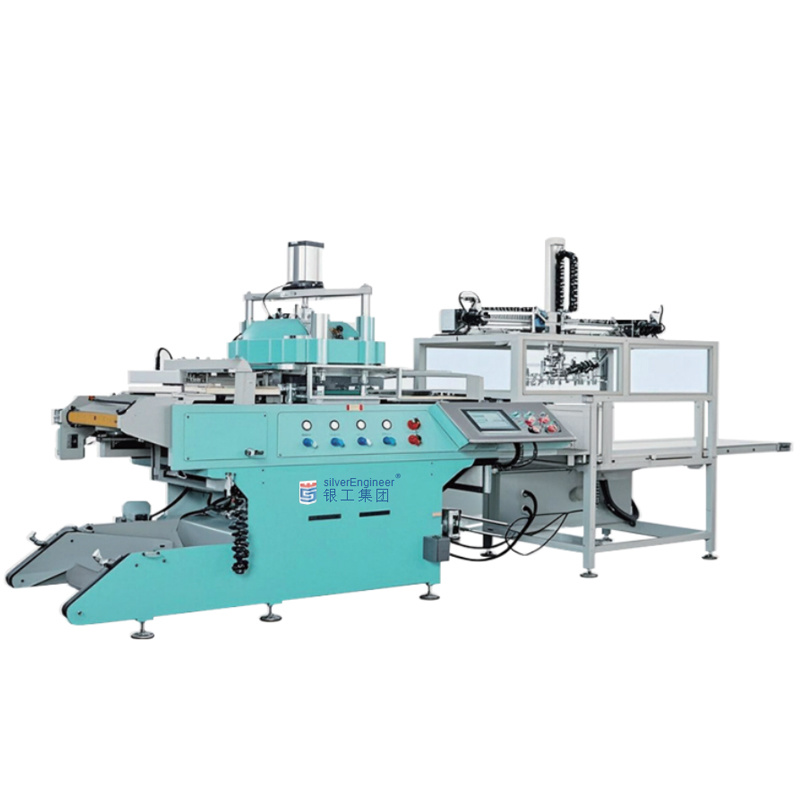

Next: Box Packing Machine

Message

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message