E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

Customize your dream packaging container, All customer achievement as the goal!

SILVERENGINEER

OTHERS

SILVERENGINEER

·It adopts thickened special high-quality die steel, strictly in accordance with European die steel standards, in line with the hygienic requirements of the production of food non-washing containers.Mould Material

OTHERS

·Using light and thin domestic 45 steel and low-end CR steel, not wear-resistant, poor strength, easy deformation, not in line with food-grade clean container production health requirements.SILVERENGINEER

·Core components are self-CNC and slow wire cutting machine processing, heat treatment and aluminum surface hardness treatment more wear-resistant.Processing Technology

OTHERS

·Core components rely on external processing, precision no guarantee, no comprehensive heat treatment, no surface treatment of aluminum, easy to wear and tear.SILVERENGINEER

·Provide 2-year warranty, project follow-up service, basic English communication skills, improve the use of the manual and after-sales video.After Service

OTHERS

·After-sales no guarantee, no team quick feedback, no communication training ability, no perfect manual and after-sales tools.SILVERENGINEER

·12 years industry experience, design follow the personalized, differentiated, custom mold can achieve high-speed automatic stacking production goalsCustom Experience

OTHERS

·The design method is old, no customized optimization product capacity, product scrap rate is high, low strength, many molds can not achieve stable high-speed automatic production.SILVERENGINEER

·By optimizing the product structure and cutting arrangement process, the lower scrap edge rate was achieved, and the scrap edge rate was reduced by 2-5% compared with the same type of die in the market.Scrap Rate

OTHERS

·Die Design has no optimization thinking and ability, does not pay attention to the reasonable optimization to reduce the scrap rate, the production cost is high 2-5% .SILVERENGINEER

·It has better applicability to aluminum foil materials of different alloys, suitable for 7 types.Aluminium Erviceability

OTHERS

·The applicability of aluminum foil to different alloys is not good, which is not conducive to the replacement of new materials, and is not conducive to providing a better product scheme.SILVERENGINEER

·Perfect Chinese and English instructions, easy to master the daily maintenance, all die drawings are accurately filed, easy to replace the same new accessories.Maintenance

OTHERS

·The applicability of aluminum foil to different alloys is not good, which is not conducive to the replacement of new materials, and is not conducive to providing a better product scheme.

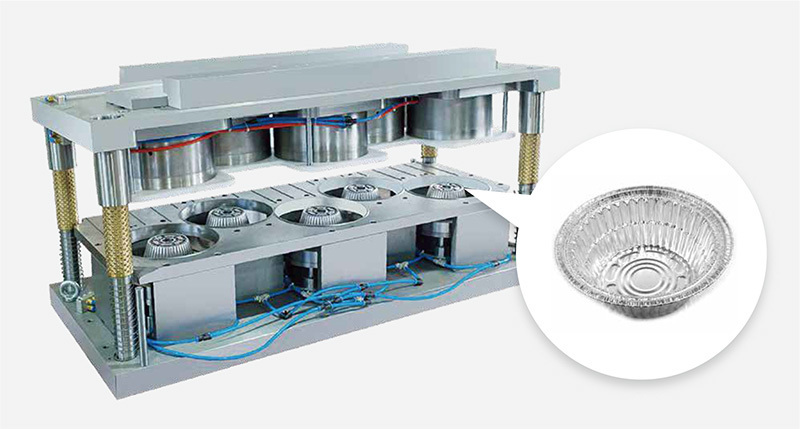

750ml pot bowl mould, product size :Dia181*H66mm, five moulds for one production, aluminum foil specification: 1025x055mm, waste edge rate: 12%; The production speed is 65 times/min, and the defect rate of 3004 alloy is less than 0.05%.

Zero waste edge large plate mold, product size :525x325x78mm, a mold, aluminum foil specification: 660x0.15mm, waste edge rate :5.9%, compared with the conventional mold bottom waste edge rate of 3%; The production speed is 50 times/min, and the defect rate of 3004 alloy is less than 0.01%.

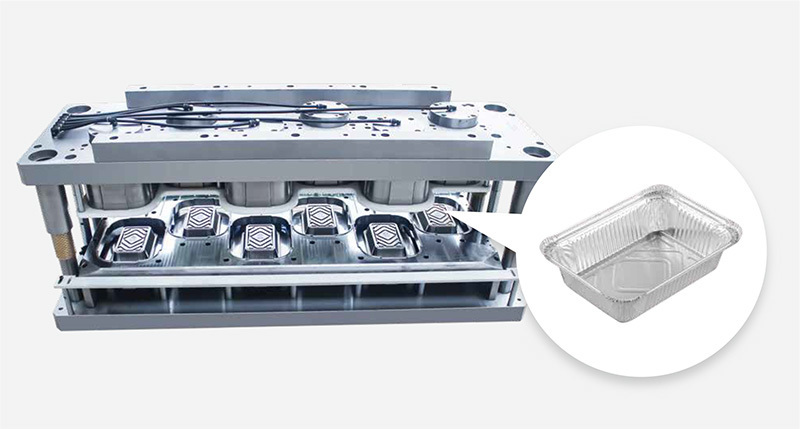

900ml rectangular lunch box mold, product size :214x146x49mm, six molds for one production, aluminum foil specification: 1387x0.04mm, waste edge rate: 11.5%; The production speed is 55-65 times/min, and the defect rate of 3003 alloy is less than 0.01%.

The product size is 218x126x70mm, one out of two molds, aluminum foil specification: 462x0.135mm, waste edge rate is 16%, the production speed is 50 times/min, 8006 alloy defective rate is less than 0.1%.

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message