E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

Mechanical equipment

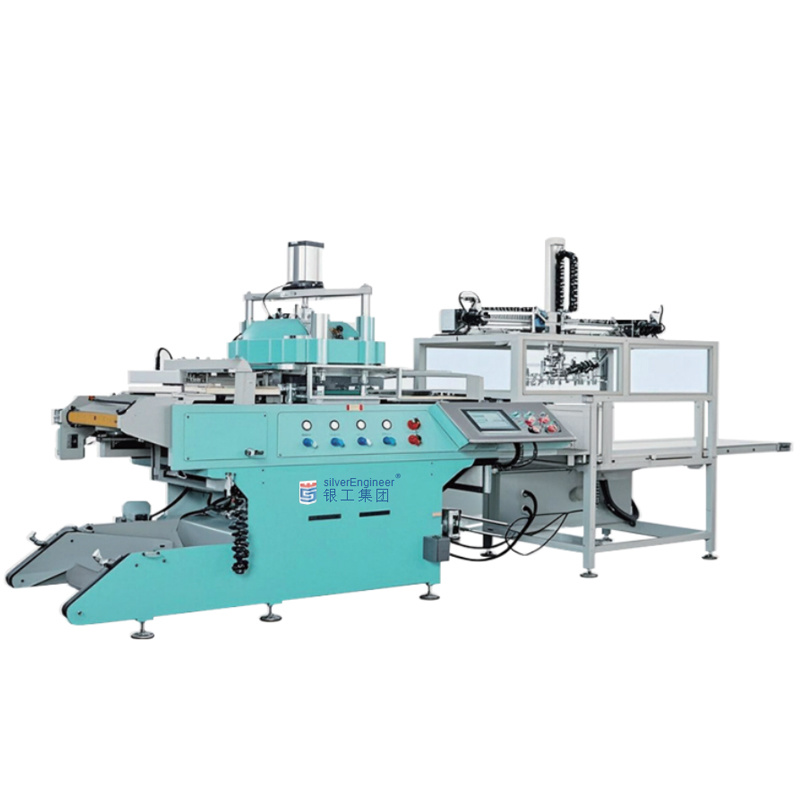

SP-60T

Key words:

Category:

Details

Drawing of structure

Technical Data

|

Model |

SP-30T |

|

|

Scrap Enter No. |

2pcs for Two Production Line |

10pcs for Ten Production Line |

|

Hydraulic Power |

30TONS |

60TONS |

|

Main Motor |

5.5KW SIEMENS |

15KW |

|

Packaging Size |

400x400x100~300mm |

600x600x100-700mm |

|

Feed Open Size |

300x300mm |

500x500mm |

|

Control Way |

Auto/Semi Auto |

Auto/Semi Auto |

|

Hydraulic Units |

Three Units |

Three Units |

|

Out Bale Way |

Auto Push |

Auto Push |

|

Separate Size |

600mm |

1200mm |

|

Electrical Appliance |

Schneider / OMRON |

DELEXI |

|

PLC Brand |

Mitsubishi |

Mitsubishi |

|

Machine Size |

1500x1200x2500mm |

5350x1000x1500mm |

|

Machine Weight |

1500KGS |

4000KGS |

Description

The Automatic Aluminum Foil Scrap Hydraulic Baler System is an indispensable part of the Automatic Aluminum Foil Container Production Line. Without the Scrap system, the production line will not be able to produce fully automatically, the speed of feeding production will be greatly reduced, and there will be messy scrap foil garbage around the equipment, which will seriously affect the safety and environment of production management. At the same time, the purchase price of uncompacted scrap foil is far lower than that of neatly compacted scrap foil.

Performance

SP-30T model is a Vertical Hydraulic Baler with simple and convenient operation, stable operation and simple maintenance. It can be selected under automatic and manual working conditions. It is suitable for small projects. One set Baler can handle 1-2 sets of Aluminum Foil Container Production Lines.

SP-60T model is a Horizontal Hydraulic Baler with simple and convenient operation, stable operation and simple maintenance. It can be selected under automatic and manual working conditions. It is suitable for big projects. One set Baler can handle 6-10 sets of Aluminum Foil Container Production Lines.

Working principle

Working Principle: After the scrap aluminum foil is cut from mould, it is absorbed by the scrap sucker fan and cut into about 30cm length,then it enters the Hydraulic Baler Bin through the pipe; The Detection Sensors will start the main motor when Baler Bin is Full, then the main Hydraulic Cylinder will operate to compress the scrap aluminum foil in the bin until the pressure reaches the set pressure value; then the Baler will automatically open the bin door, and automatically push out the compressed Scrap Aluminum Foil Block,then Shut down the main motor after closing the bin door, and continue to wait for the next PLC command to restart.

Message

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message