E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

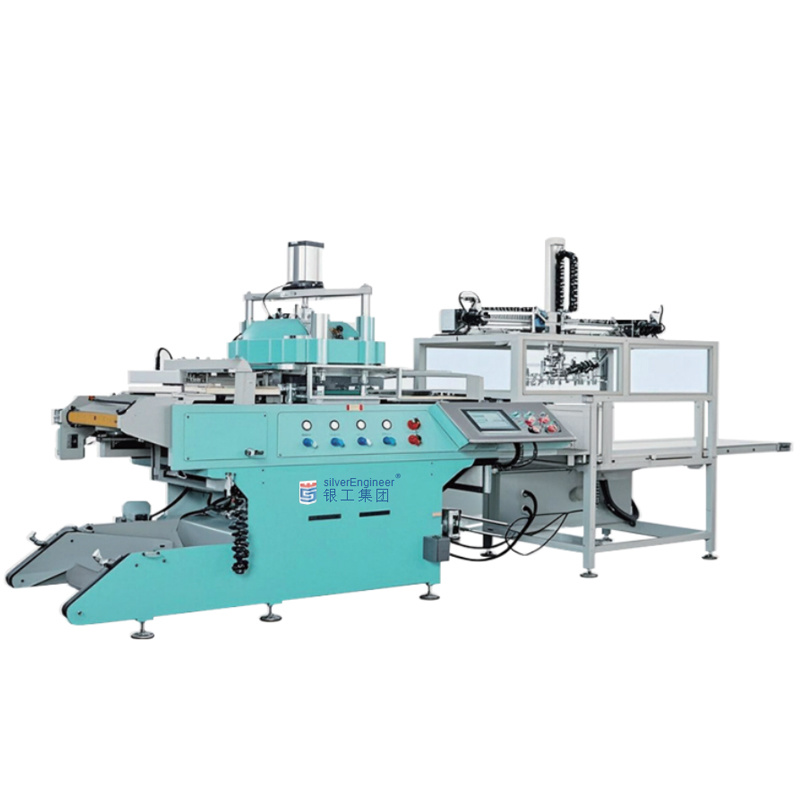

Mechanical equipment

SEAC-1700

Key words:

Category:

Details

Technical Data

| Model | SEAC-1700(4-7Cavities) |

|

Nominal Force |

630KN |

|

Main Motor |

11KW, SIEMENS |

|

Stroke Range |

150-300mm |

|

Adjustable Speed |

30-80times/min. |

|

Number of Solenoid Value |

10sets (2*5cacities) |

|

Bed Plate Dimension |

L1100xW920mm,2sets movable plate |

|

Max.Mould Dimension |

L1200xW850xH450mm |

|

Number of Air Tank |

5units |

|

Press Lubricant Solution |

Solid Lithium Grease, Manual Filling |

|

Max. Width of Foil Passage |

900mm |

|

Feeder Tension Control |

Automatic by Ultrasonic Sensor |

|

Max.Diameter of Foil Roll |

600-1500mm |

|

Feeder Precision Control |

±0.1mm, Mitsubishi Servo System |

|

Stacker Belt Size |

L2000xW900mm |

|

Min.Size Stack Available |

120x120mm |

|

Products Stacking Size |

One lane: L500xW800xH350mm Two lane: L500xW400xH350mm |

|

|

Three lane: L500xW250xH350mm Four lane: L500xW190xH350mm |

|

Lifting System |

SMC Servo Cylinder |

|

Main Electric Brand |

Mitsubishi,SMC,Schneider,OMRON,SIEMENS |

|

Production Line Dimension |

7100x2500x3500mm |

|

Production Line Weight |

11,500KGS |

Description

SEAC-1700 adopts higher precision customized H-Type Eight-Face Guide Rail Mechanical Press. Mainly use for Wrinkle Wall Container production. The software and hardware of the whole production line adopt Mechatronics design, which is beautiful and generous. The whole automatic production line is mainly composed of Feeder, Press, Stacker and Scrap System unites. The electrical control system of the whole production line is divided into two parts: the integrated electrical control cabinet of three units of Feeder, Press and Scrap System adopts independent system design, which is safe and anti-interference. The touch screen is hung on the left side of the Press, which is convenient for operation and does not occupy space; The electrical cabinet of the Stacker is installed on one side of the Stacker to independently control all parameter settings and operation. The PLC program logic of the whole production line is perfectly matched, which greatly improves the Production Efficiency of the whole machine and the Rationality of Program Control logic, and is more smart humanized.

Advantages

1.High Configuration Mitsubishi FX5U-64M PLC:stronger function, more stable and faster response, and 30 sets of mould processing parameters are

stored and memorized.

2.Adopt Cantilever Rotatable Integrated Touch Screen Control Structure: more flexible, safer and less space than the traditional mobile console.

3.The worktable adopts split 8 groups of lifting steel

balls: one worker can unload the mould and change the mould within 15 minutes, which is really fast and labor manpower saving.

Message

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message