E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

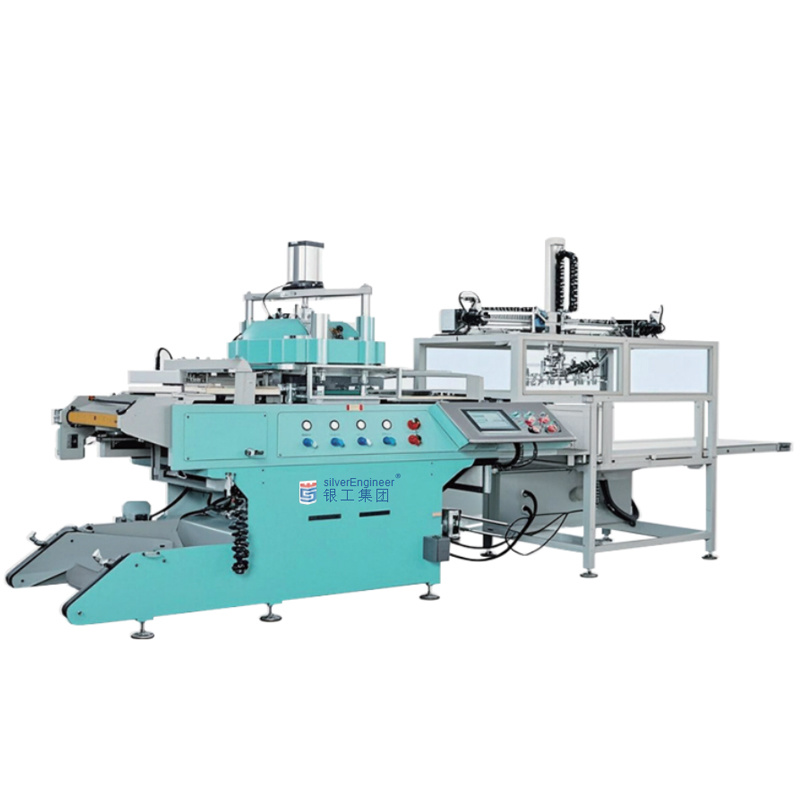

Mechanical equipment

Details

Drawing of structure

Technical Data

|

Model |

AS-900 |

AS-1300 |

AS-1500 |

|

Lane Quantity |

1-4lanes |

2-6lanes |

3-7lanes |

|

Belt Dimension |

L2000xW900 |

L2000x1300mm |

L2000x1500mm |

|

Belt Height |

1050-1300mm |

1050-1300mm |

1050-1300mm |

|

Min. Container Size |

100x100mm |

100x100mm |

100x100mm |

|

Products Stacking Size |

One lane: L500xW800xH350mm |

Three lane: L600xW350xH350mm |

Four lane: L600xW300xH350mm |

|

Lifting System |

SMC Servo Cylinder |

SMC Servo Cylinder |

SMC Servo Cylinder |

|

D etect &Counting |

Sensor and Optical Fiber |

Sensor and Optical Fiber |

Sensor and Optical Fiber |

|

Main Motor |

1.2KW SIEMENS |

1.5KW SIEMENS |

2KW SIEMENS |

|

PLC Touch Screen Brand |

Mitsubishi |

Mitsubishi |

Mitsubishi |

|

Machine Size |

2500x1200x1500mm |

2500x1500x1500mm |

2500x1800x1500mm |

|

Machine Weight |

1500KG |

1800KG |

2000KG |

Description

Auto Stacker is a necessary part for the production of aluminum foil containers to achieve full automation. As aluminum foil containers are widely used in the field of wash free food packaging, manual collection of each product is bound to pollute the product twice, which can not ensure food safety. In addition, the aluminum foil container is very easy to deform in the process of manual collection, counting and packaging, resulting in many deformation traces on the product surface and unsightly. Auto Stacker can be customized according to different product shapes. The switching and adjustment between different molds is simple and fast, which can greatly reduce the Labor Intensity and Labor Cost of workers, improve efficiency and improve the profit space of products.

Performance Comparison

Auto Stacker adopts aluminum profile structure, and the belt adopts Two-Stage structure, which is conducive to the production of aluminum foil container with high speed, stability and no blockage. Panasonic Sensor for Product Detection Out from mould, Detection Moving, Fiber Counting and SMC lifting control are automatically controlled by Mitsubishi PLC program, Independent intelligent control system is convenient, safe and reliable. The height adjustment of belt is flexible and convenient.

Message

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message