E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

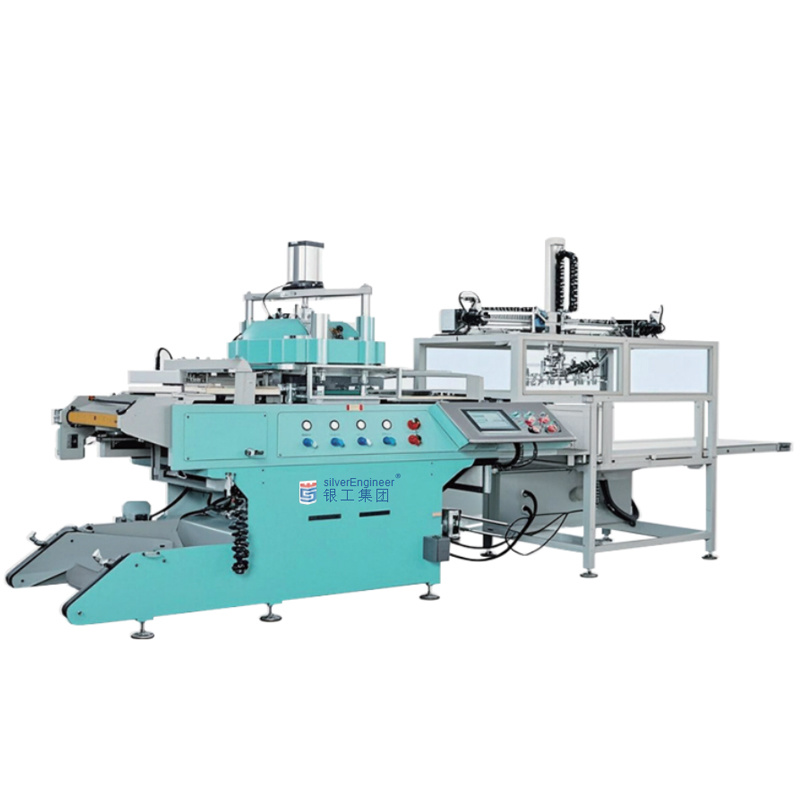

Mechanical equipment

SEPL-5060/5575

Key words:

Details

Technical Data

| Model | SEPL-5060 | SEPL-5575 |

|

Max.Forming Area |

510x620mm |

550x750mm |

|

Max.Forming Depth |

100mm |

120mm |

|

Material Thickness Range |

0.10-1.0mm |

0.10-1.0mm |

|

Knife Length |

APET:6800mm/OPS:9000mm |

APET:8000mm/OPS:11000mm |

|

Air Pressure |

0.7Mpa |

0.7Mpa |

|

Air Consumption |

1500L/min |

1800L/min |

|

Water Consumption |

5L/min |

8L/min |

|

Power Consumption |

7.5kw/h(Approximate) |

10kw/h(Approximate) |

|

Total Heating power |

24kw |

30kw |

|

Total Motor power |

8kw |

9kw |

|

Power Supply |

AC 380V±15V 50/60HZ |

AC 380V±15V 50/60HZ |

|

Production speed |

600-1200Cycles/h |

600-1200Cycles/h |

|

Max. Material Roll Diameter |

710mm |

800mm |

|

Max. Sheet Width |

680mm |

810mm |

|

Dimensions |

Machine:2950*1550*2350mm |

5000*1750*2500mm |

|

Weight |

3500kg |

4800kg |

Description

This series of machines is an integrated design of mechanics, electricity and pneumatics, with a PLC control system and touch screen operation. It is a plastic thermoforming equipment that can complete the processes of sheet feeding, heating, forming, cutting and stacking in one go. It is applicable to thermoplastic materials such as BOPS, PS, APET, PVC, PLA, etc., and can be used to form various products such as LIDS, boxes, plates, trays, and connected boxes, such as lunch box LIDS, sushi LIDS, paper bowl LIDS, aluminum foil LIDS, mooncake trays, pastry trays, food trays, supermarket trays, oral liquid trays, and medical injection trays.

Performance

The Production Process:

1.The servo drive works to achieve smooth and energy-saving effects

2.Memory storage system

3.Switch of working mode

4.Provide intelligent diagnostic analysis

5.In-die cutting ensures the consistency and accuracy of product edge cutting

6.Low energy consumption and high utilization rate

7.The mechanical hand rotates 180 degrees

Message

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message