E-mail : info@silverengineer.com

Whatsapp & Wechat :0086-15216689661

-

AboutSE was founded in 2010 located in Shanghai. In 2014 moved to Jiashan, Zhejiang Province. We were committed to providing overall solutions for the transformation and upgrading of the Global Aluminum Foil Packaging Industry in the New Era.

-

MACHINEAluminum Foil Container Machine Foil Feeding Machine Foil Scrap System Foil Lid Cutting Machine Foil Rolls Machine Pop Up Sheet Machine Paper Sheet CuttingMachine Paper Die Cutting MachineWith 4 Moulds Automatic Plastic LidThermoforming Machine

Mechanical equipment

Box Packing Machine

Key words:

Category:

Details

|

Name |

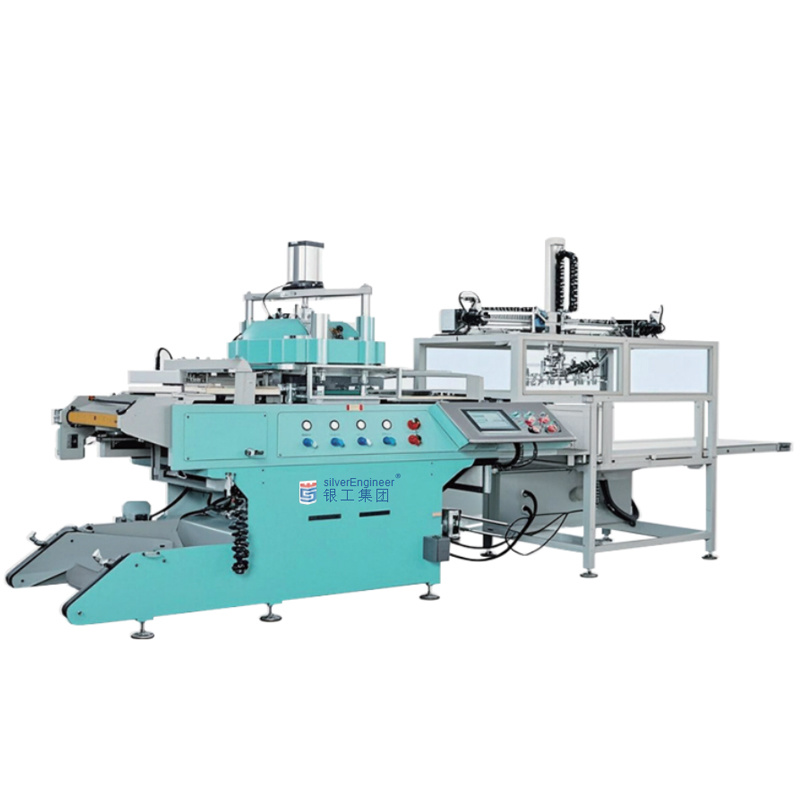

Automatic Roll Box Packing Machine Automatic Pop Up Foil Packing Machine |

|

|

Application |

Cling Film, Aluminum Foil Roll, Paper Roll, Aluminum Pop Up Sheet |

|

|

Model |

SEA-80 |

|

|

Optional Unit |

Auto Rolls Feed Unit |

|

Main Structural Features:

The packaging forms of automatic feeding, box opening, box entering, glue spraying, box sealing and waste removal are adopted, with compact and reasonable structure and simple operation;

Servo / stepping motor, touch screen and PLC programmable control system are adopted. The man-machine interface display and operation are clearer and simpler, with a high degree of braking and more humanization;

The photoelectric braking detection and tracking system is adopted, which can save packaging materials to the greatest extent;

The replacement specification does not need to replace the mold, but only needs to be adjusted;

It adopts automatic shutdown and overload protection device of main drive motor when articles are not in place in the box, which is more safe and reliable;

According to the customer's requirements, the upturned safety protective cover can be adopted, which is simple to operate and beautiful in appearance.

It can realize linkage production with front-end process, labeling machine, inkjet printer, on-line weighing instrument, other production lines and other equipment;

Various automatic blanking devices and box feeding systems can be designed according to the packaging requirements.

Main Technical Parameter:

|

Packing Speed |

30-100pcs/min. |

|

Box QualityRequirement |

250-300GSM Ivory Board Or 400GSM White board |

|

Box Dimension Range(L X W X H) |

(200-460)X(30-60)X(30-60)mm |

|

Air pressure |

0.6-0.9mpa |

|

Air consumption |

<5m³/h |

|

Power supply |

380V 3P 50HZ |

|

Motor power |

4kw |

|

Machine dimension(L X W X H) |

4200X1800X1900mm |

|

Machine weight |

1800kg |

|

Noise at Work |

<50 Decibel |

Electrical Parts List:

|

Code |

Name |

Model |

Brand |

QTY. |

|

1 |

Touch Screen |

NBTW—TW00B |

OMRON |

1 |

|

2 |

Encoder |

E6B2—CW26C 360P/R2MBYOMS |

OMRON |

1 |

|

3 |

Solenoid valve |

SV522—S—DC24V |

JELPC |

5 |

|

4 |

PLC |

CPLE—N40SIDT—D |

OMRON |

1 |

|

5 |

Circuit breaker |

2P16A/1P10A/ |

CHNT |

1 |

|

6 |

Button switch |

NP2—BE102 |

CHNT |

3 |

|

7 |

AC contactor |

CJX2 1210 |

CHNT |

1 |

|

8 |

Intermediate relay |

JZF—22 |

CHNT |

4 |

|

9 |

Power Supply |

S—100—24 |

|

1 |

|

10 |

Emergency stop switch |

ZB2—BS54C |

Schneider |

1 |

|

11 |

Main Motor |

1.5Kw |

Omante |

1 |

|

12 |

Vacuum generator |

ZH20DS—01—04—04 |

SMC |

1 |

|

13 |

Inverter |

3G3JZ—A4015 |

OMRON |

1 |

|

14 |

Combination switch |

GLD11—25A |

Gree |

1 |

|

15 |

Proximity switch |

NPN |

RuiXiang |

2 |

|

16 |

Photoelectric switch |

E3Z—D61 |

OMRON |

4 |

|

17 |

Guide |

ABBAH25 |

Japan |

1 |

|

18 |

Sucker |

BV—20 |

Korea |

4 |

|

19 |

Modular |

CRIW-8ER |

OMRON |

2 |

|

20 |

Amplifier |

E3X-2D112MBYOMS |

OMRON |

2 |

|

21 |

RobaTech Hot Melt Glue spraying machine |

Ideal C5/2 |

Switzerland |

1 |

Pre: Rewinding Machine

Next: Blade Binding Machine

Message

CONTACT DETAIL

-

Add:NO.11, Baoqun West Road, Jiashan, Jiaxing, Zhejiang

Tel: +0086-18857382781

E-mail: info@silverengineer.com

Online message